Airbag is an inflatable cushion Nylon woven fabric typically made of

Nylon 6.6/66 which may be coated or uncoated and must be impermeable to

gases and flame resistant.

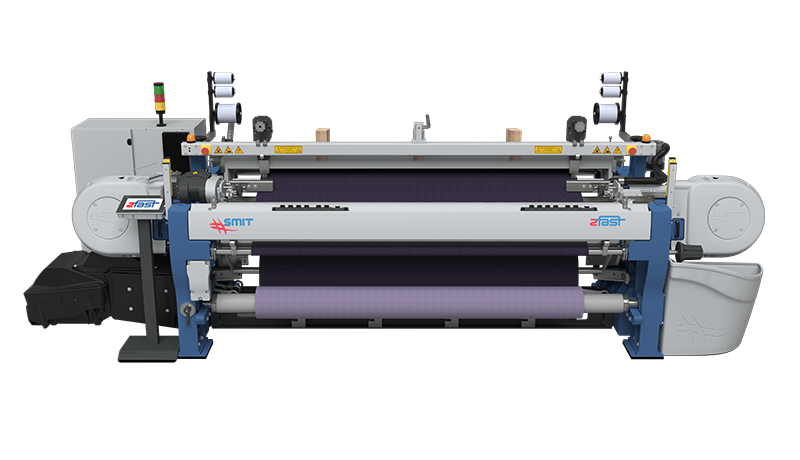

SMIT propose a dedicated machine configuration and devices.

Free flight system without hook guides is compulsory for this market with Single rapier weaving machine model 2FAST.

Versatility for further upgrading at any time, flexibility with the widest range of fabrics, excellent fabric quality productions, low rate consumption, ease of use and maintenance are the main features of SMIT weaving machines.

Weaving Machine For Airbag

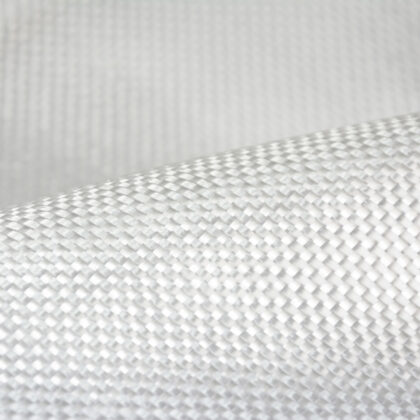

To minimize the air permeability the fabric should be woven to the tightest setting possible for the chosen yarn count and the chosen fabric construction; that is, the fabric should be woven with the maximum number of threads per unit length warp ways and weft ways. (High cover factors)

For the fabrication of the OPW (one-piece-woven) airbags many customer selected SMIT weaving machines for the high fabric qualities and efficiencies at higher speed.

– Material: PA6/6.6

– Yarn count : 300-800 Den multifilament the standard

The standard configuration machines:

● Model: 2FAST

● 260, 290, 320cm machine reed width

● Dobby 12-16 lever or Jacquard

● 4 weft feeders version

● Thermal cutting

● Reinforced slay bar

● Electronic rotative weft cutter or Electronic weft cut

● Double back rest bar – Optionial

● External winder – Optional

2FAST & ONE: for any type of AIRBAG

By ONE machine the weft insertion performed by a single rapier and the numerous improvements in mechanic and electronic groups increase the already high quality standards.ONE AND 2FAST : FAST AND EASY!

What fabric do you want to produce?

Do you want to customize your machine?

Can’t find the fabric you want?

"*" indicates required fields