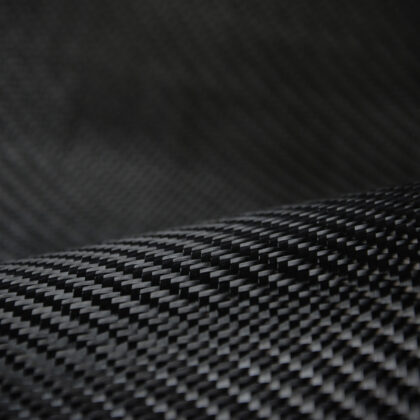

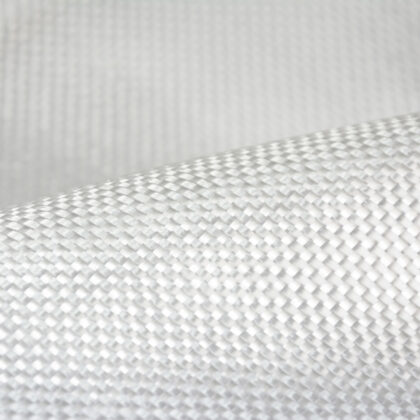

Filter fabric production as technical fabric for many final use. From water and air filter, medical filter and other in technical industry.

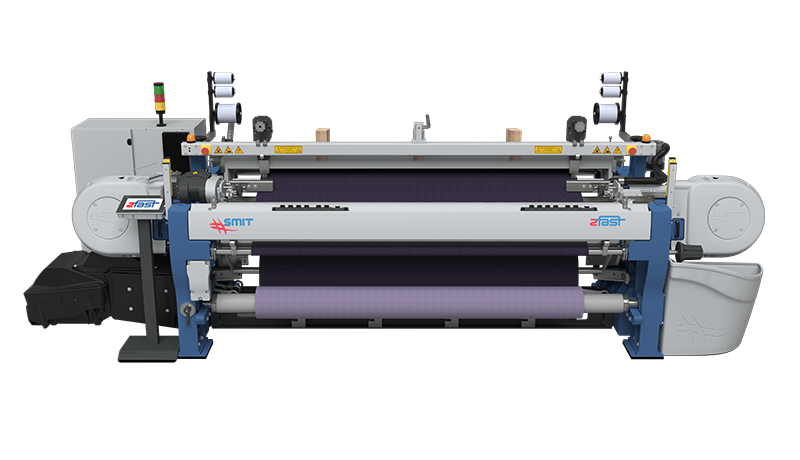

SMIT proposes a dedicated machine configuration and devices.

Free flight system without hook guides is compulsory for this market with single rapier weaving machine model 2FAST or ONE.

Versatility for further upgrading at any time, flexibility with the widest range of fabrics, excellent fabric quality productions, low rate consumption, ease of use and maintenance are the main features of SMIT weaving machines.