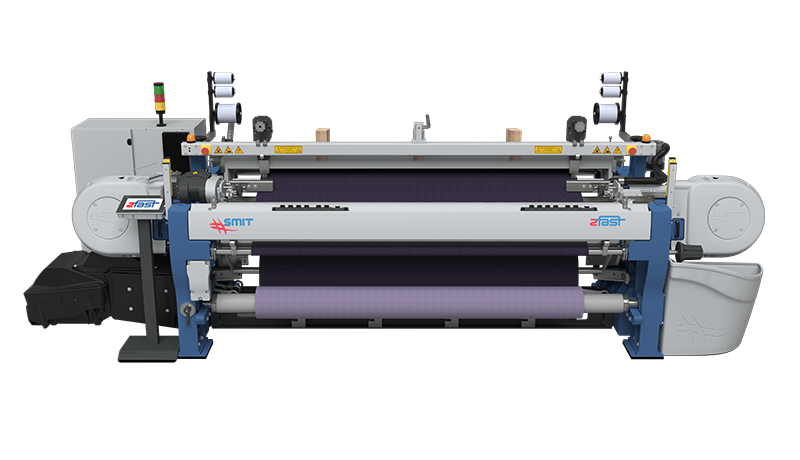

Home textile fabric production is another of the main market for SMIT with dedicated machine configuration and devices.

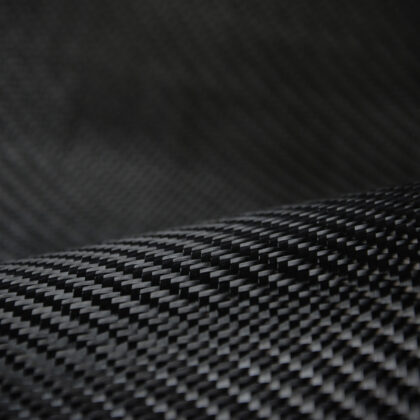

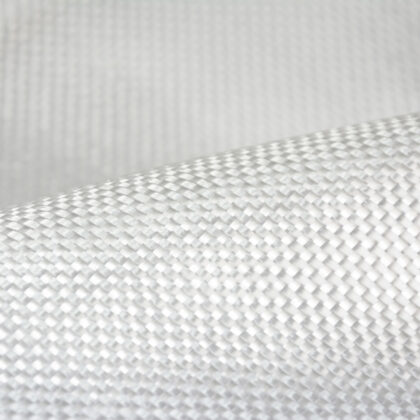

For home textile fabrics, advanced mechanical design and technological parameters minimize stress on the weft and on warp yarns. SMIT free-flight carbon composite ribbons without hook guides system provides the fastest weaving width change, high textile efficiency and top fabric quality even with the most delicate yarn fabrics.

Versatility for further upgrading at any time, flexibility with the widest range of fabrics, excellent fabric quality productions, low rate consumption, ease of use and maintenance are the main features of SMIT weaving machines.

SMIT is considered the machines with best and higher range of weft yarn insertion.

Custom made self-retaining grippers, easy to adjust and stable while weaving, are engineered for a wide range of weft material and counts.